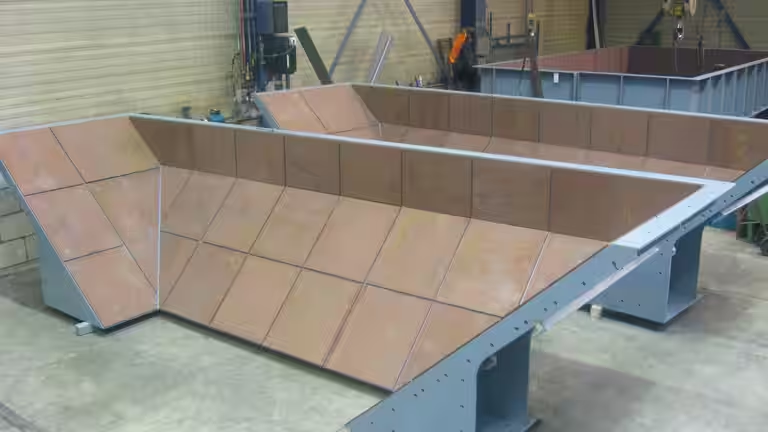

Hardox Wear Plate

Hardox Wear Plate is a very wear resistant steel plate, which is manufactured by SSAB and sold worldwide. As this steel wears very slowly even under heavy mechanical loads, it is used in many areas of industry.

Rime processes Hardox Wear Plate

Our professional staff cut Hardox Wear Plate up to a maximum sheet thickness of 25 mm by laser using the latest machine technology. Our machine technology also allows bending in different sheet thicknesses.

Contact us if you need wear-resistant parts made of Hardox Wear Plate! We always have different thicknesses in stock and can provide you with further information.

Characteristics

Hardox Wear Plate is characterized by an even flatness, high hardness and high strength. Due to these important properties, thinner plate thicknesses can be processed for the manufacture of components made of wear plates with higher hardness levels. The weight of the constructions made from them can be reduced by a significant amount.

The very good welding and machining properties allow later repairs of wearing parts without problems.

Bending of Hardox Wear Plate

Wear plates such as Hardox Wear Plate can be cold formed by bending and roll bending. It must be noted that damage and rust deposits can reduce the flexibility. Removing these defects by grinding is essential.

The strong force applied to the high-strength steel plate can lead to cracks on the surface and parts of the workpiece surface can be blasted off in the bending zone. Therefore, it is important to ensure that the bending radius is adequately large according to the material thickness. For material thicknesses up to 8mm, a radius of 4 x sheet thickness must be selected, and for thicknesses above 8mm, a minimum radius of 5 to 6 times the material thickness must be chosen.

Drilling and tapping

Although Hardox Wear Plate is extremely resistant, holes and threads can be drilled into this wear plate. For this purpose, high-speed steel or carbide drills, 4-edged taps and appropriate machine technology are required.

Different varieties

Today, this steel is available in various grades. They differ in hardness, ductility, bendability and the possibility of welding.

Hardox wear plate 400 / 450

- HARDOX wear plate 400

Plate thickness: 3 - 130 mm - HARDOX wear plate 450

Plate thickness: 3 - 80 mm

Used for the production of dump trucks, sieves, slideways, equipment for crushing rocks, excavators or even conveyor systems - very good weldability

Hardox wear plate 500 / 550

- HARDOX wear plate 500

Plate thickness: 4 - 32 mm / 32 - 80 mm - HARDOX wear plate 550

Plate thickness: 10 - 50 mm

Used in conveyor systems, knives and blades, buckets for excavators, gear wheels, crushing plants - high demands on wear resistance

Hardox wear plate 600

- Hardox 600

Plate thickness: 8 - 50 mm

Application with slides, crushers, hammers or shredders - high resistance to wear

Hardox wear plate HiTuf

- Hardox wear plate HiTuf

Plate thickness: 40 - 120 mm

Used for tear-off tools or cutting edges - good combination of ductility and wear resistance

Hardox wear plate Extreme

- Hardox Extreme

Plate thickness: 10 mm and 25 mm

Used for hammers, shredders, wear protection plates and cutters - extremely high wear resistance properties

See also

BRINAR

BRINAR is a wear-resistant steel which is used in mechanically highly stressed areas.

Read moreConstruction Steel

Construction steel has excellent mechanical properties and can be processed very well.

Read moreCopper

Copper is used in many ways for industrial and construction purposes. It is also suitable as an alloying element.

Read more