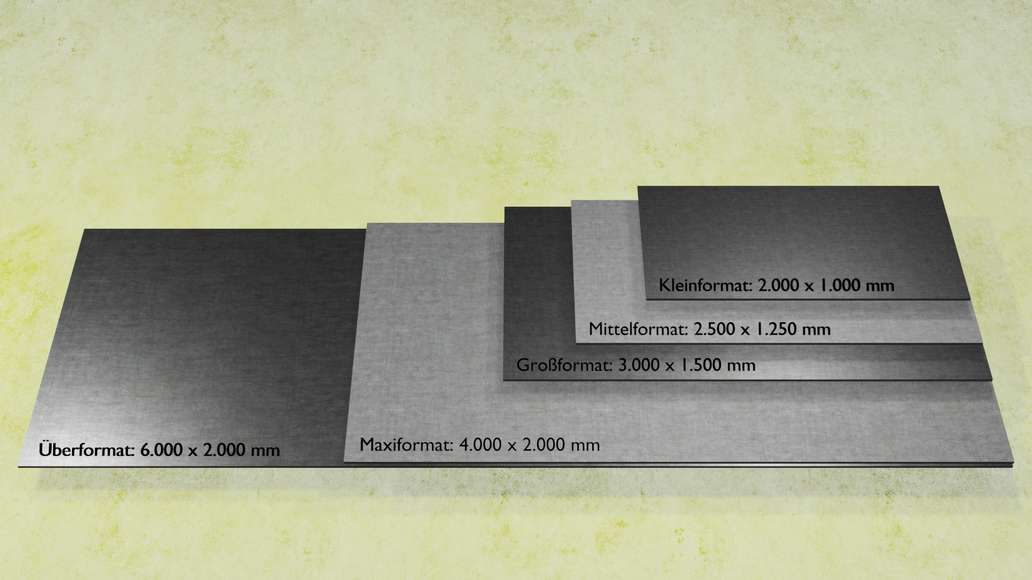

Sheet Metal Formats

Metal sheets are produced in the standard formats as follows:

- Small format

1,000 x 2,000 mm - Medium format

1,250 x 2,500 mm - Large format

1,500 x 3,000 mm - Maxi format

2,000 x 4,000 mm - XXL format

6,000 x 2,000 mm

Oversize Formats

- 2,000 x 6,000 mm

- 2,500 x 6,000 mm

- 3,000 x 6,000 mm

These sheet formats are also available in lengths of 8,000 and 12,000 mm as standard.

Other Oversize Formats

- 3,500 x 7,000 up to 14,000 mm

- 4,000 x 12,000 up to 16,000 mm

It is technically possible to produce even larger metal plates. However, these plate metals are difficult to transport and can only be processed at great difficulty.

See also

Brinell hardness test

Performing the hardness test by means of a ball pressure test according to the Swedish engineer Johann August Brinell.

Read moreCoil

Plate metal that is rolled-up to coils is easier to transport and requires less space in the warehouse

Read moreCorrosion

Corrosion is a natural process and damages most metals. What types of corrosion are there?

Read more